Author: Steve

-

Integrated Inspection

Based on customer demand and emerging industry trends NSI has focused specifically on providing systems that allow an adhesive component, label or other die-cut adhesive part, to be inspected prior to placement on a substrate component. These systems provide our customers a massive competitive advantage by reducing or completely eliminating the opportunity for an out…

-

Print and Apply Automation

NSI, using our print and apply applicator products has configured dedicated automation systems for specific print and apply applications. For Tube and Vial Labeling we offer our FLEX Tube Pro systems. For complex label and wrap applications we’ve configured our PL Applicator with Reject Options systems. FLEX Tube Pro Fully Automated Tube and Vial…

-

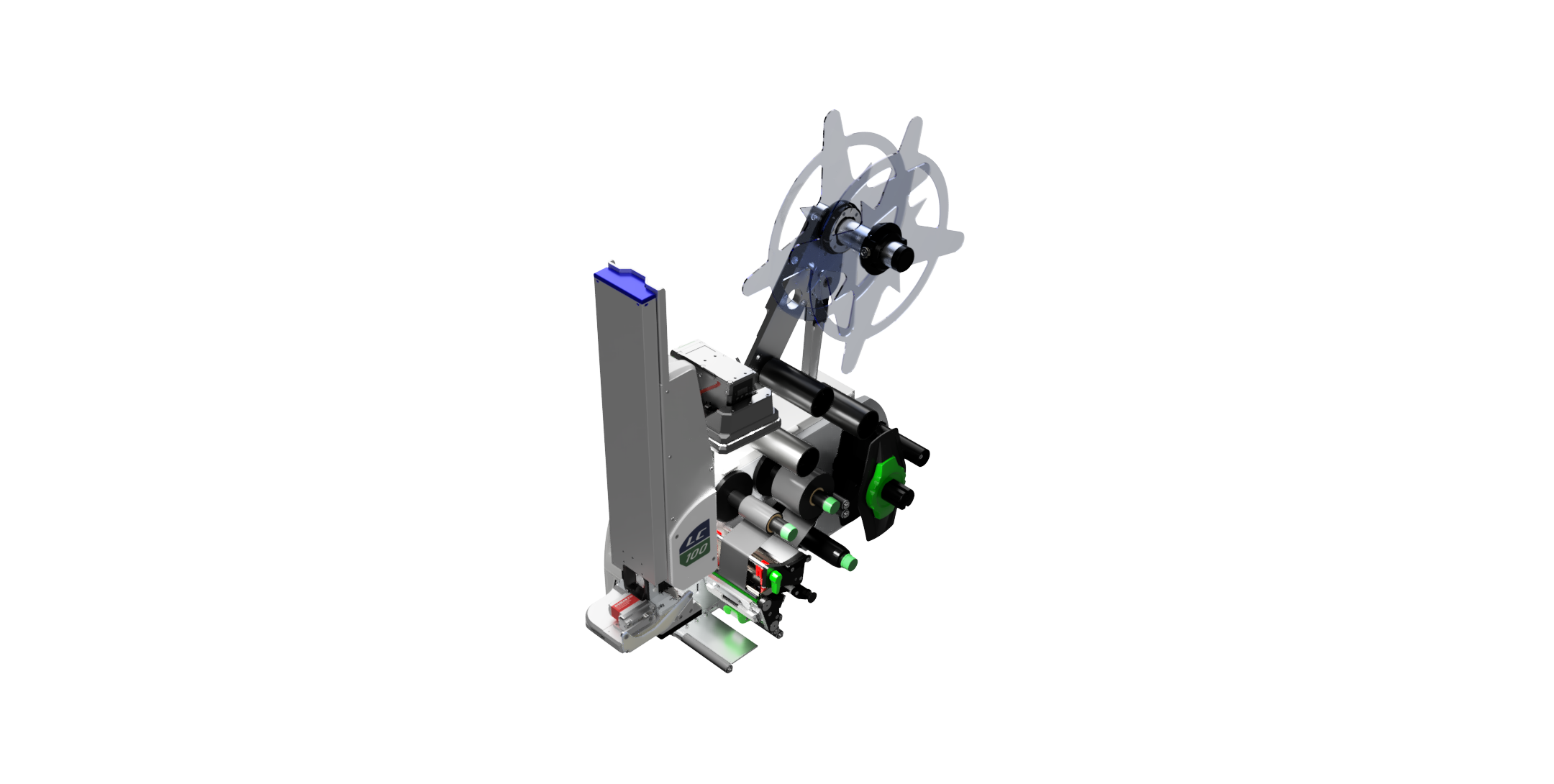

LC100i-C Applicator

Description The LC100i-CTM is a compact configuration of our highly advanced on-demand ‘print and apply’ system designed for challenging labeling requirements. Based on customer requests we relocated the roll payoff above the main body of the system to reduce the overall system footprint. High resolution (600 dots per inch) thermal transfer print quality combined with…

-

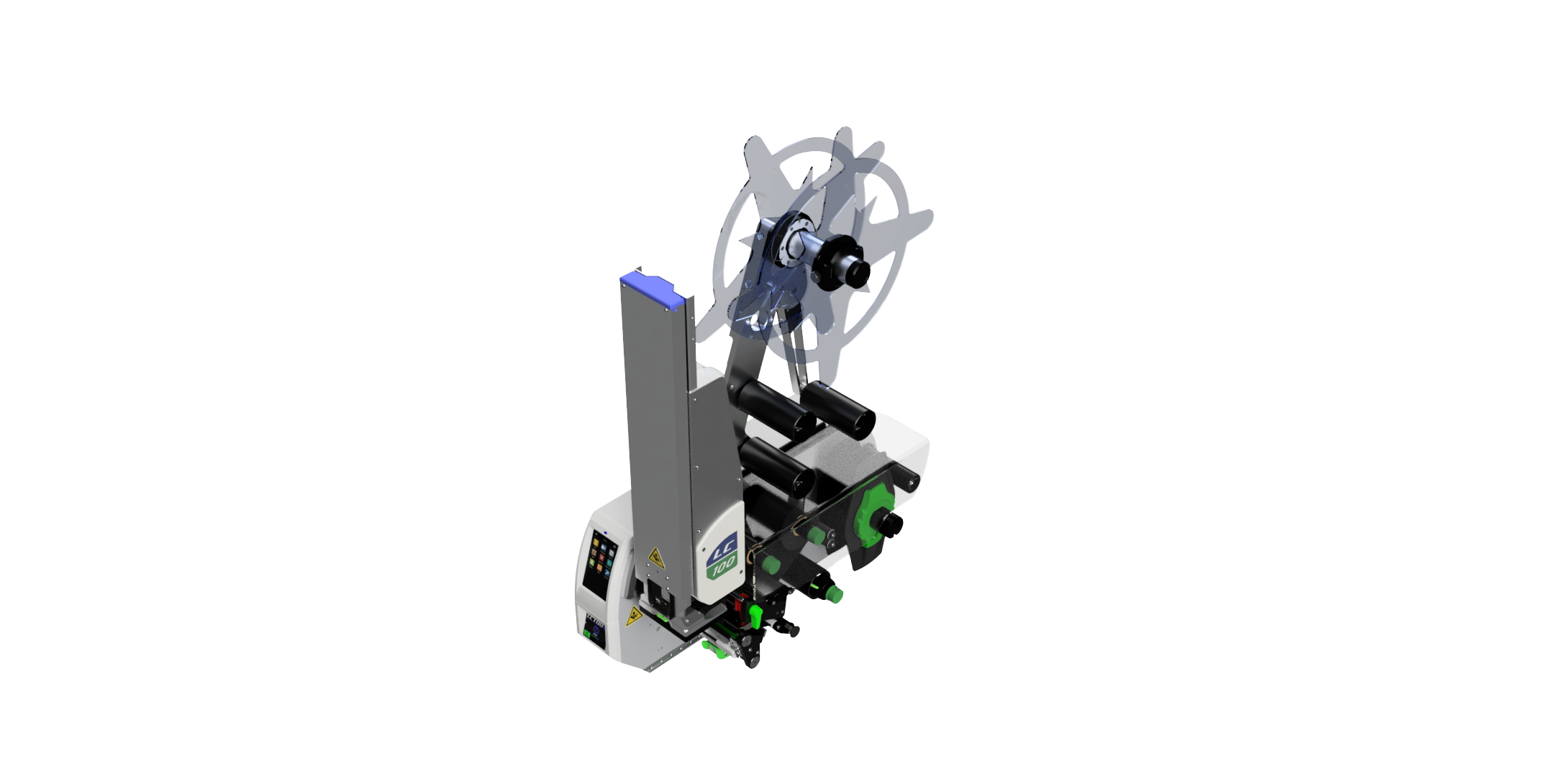

LC/LG – On Demand

LC100TM Series Print and Apply and LG100TM Label Glide Systems are NSI’s offering for ‘on demand’ Print and Apply Applicators. The LC100 Series offers 600 dpi thermal transfer print quality and precision placement. LC100i Applicators include our integrated smart LabelBotTM Tamp Actuator. LC100rTM Robot Mode Feeders are configured to print and present a component for…

-

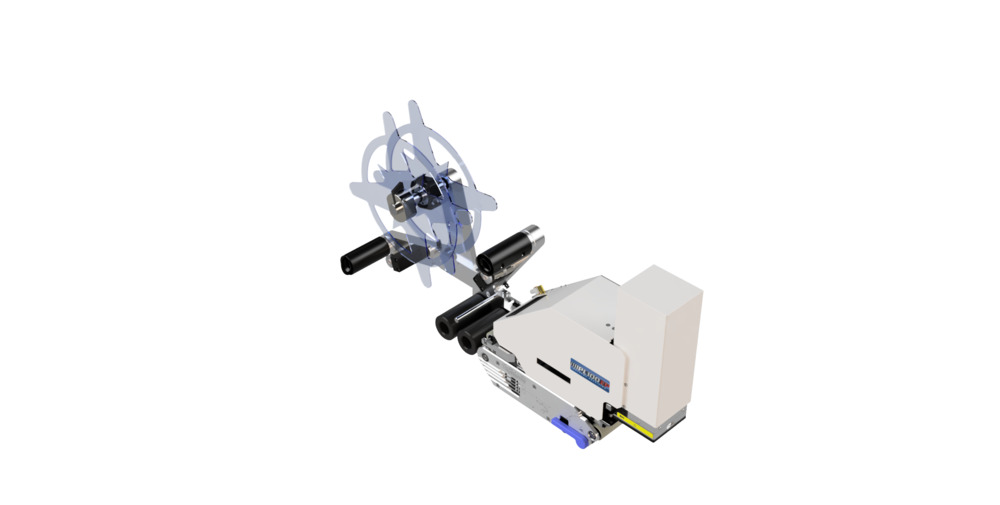

PL Series TTP

PL100 and PL165 Series Applicators can be configured with a Thermal Transfer Printer (TTP) module to provide a ‘Print and Apply’ system. These systems are ideal for applications that don’t require ‘on demand’ printing and can be satisfied with batch printing. These Applicators provide all of the benefits of our PL Series Applicators with the…

-

MD&M West 2025

MD&M West 2025 Anaheim, CA (February 5 – 7, 2025) Please visit us in Booth 3275 at the MD&M pavilion in the Anaheim Convention Center in Anaheim, CA from February 5 – 7, 2025. We will be displaying both a PL100EPi-SS (SideScan) Applicator and an LC100i Applicator in the booth. The PL100EPi-SS features automatic positioning…

-

PL100EPr-C Compact Feeder

Description The “All-Electric” PL100EPr-C Feeder is our compact version of the PL100EPr unit. It provides a highly accurate and reliable feed and peel system of virtually any shape of die-cut adhesive component. No pneumatics simplifies setup and maintenance. It provides capacity for components up to 100 x 100mm in size. The PL100EPr-C is configured specifically…

-

PL100r-C Compact Feeder

Description The “All-Electric” PL100r-C Feeder is our compact version of the PL100r unit. It provides a highly accurate and reliable feed and peel system of virtually any shape of die-cut adhesive component. No pneumatics simplifies setup and maintenance. It provides capacity for components up to 100 x 100mm in size. The PL100r-C is configured specifically…

-

PL100EPi-ET200 Applicator

Description The PL100i-ET200 Applicator provides highly accurate and reliable placement of virtually any shape of die-cut adhesive component. It provides capacity for components up to 100 x 100mm in size. The PL100i-ET200 is configured specifically for integration into automated assembly solutions. It includes all of the hardware necessary for operation including an electric precision-guided Tamp…

-

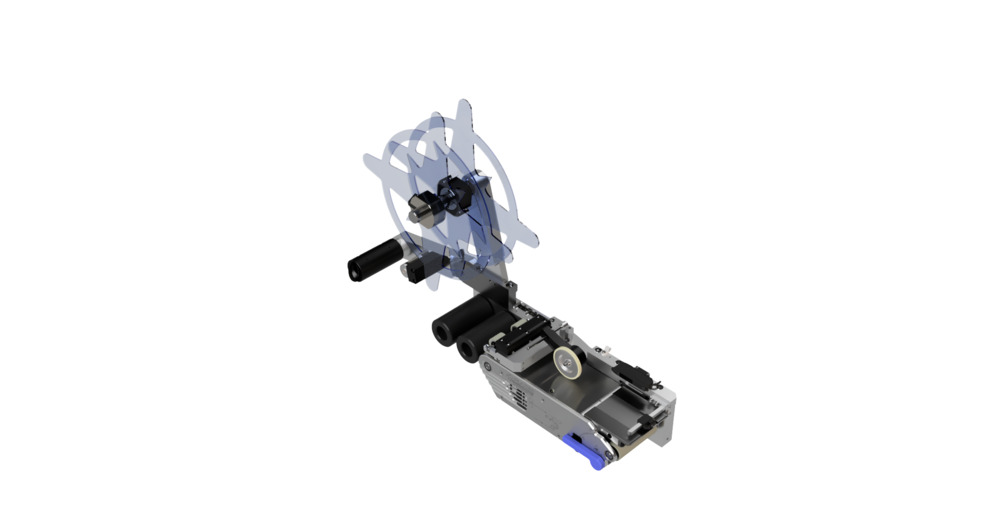

PL165 Robot Mode

Nautilus Systems, Inc. (NSI) All-Electric PL165 Robot Mode Feeders are configured specifically for integration with external Robotic or Picker devices to provide a highly accurate and reliable feed and peel system of virtually any shape of die-cut adhesive component. The Robot Mode Feeders include all hardware necessary for operation including the base Feeder, a Payoff…