Description

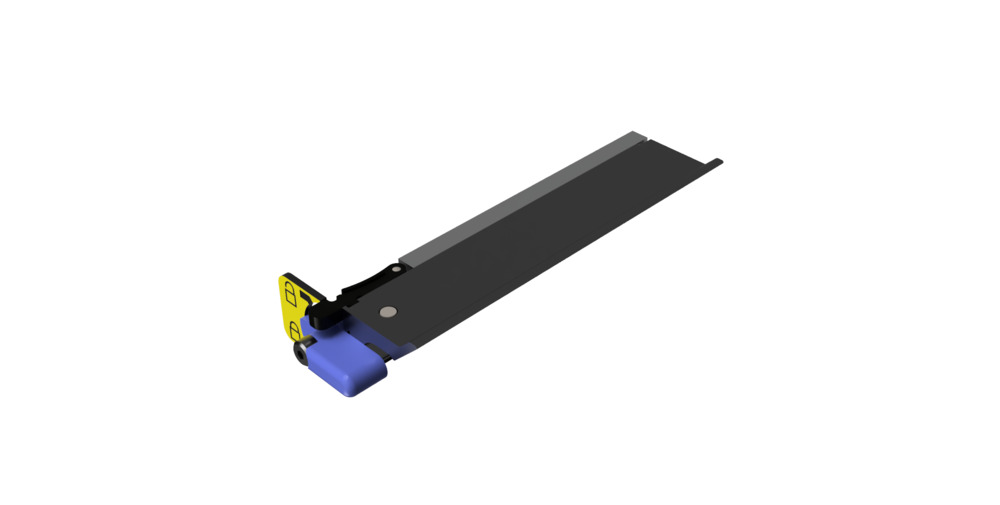

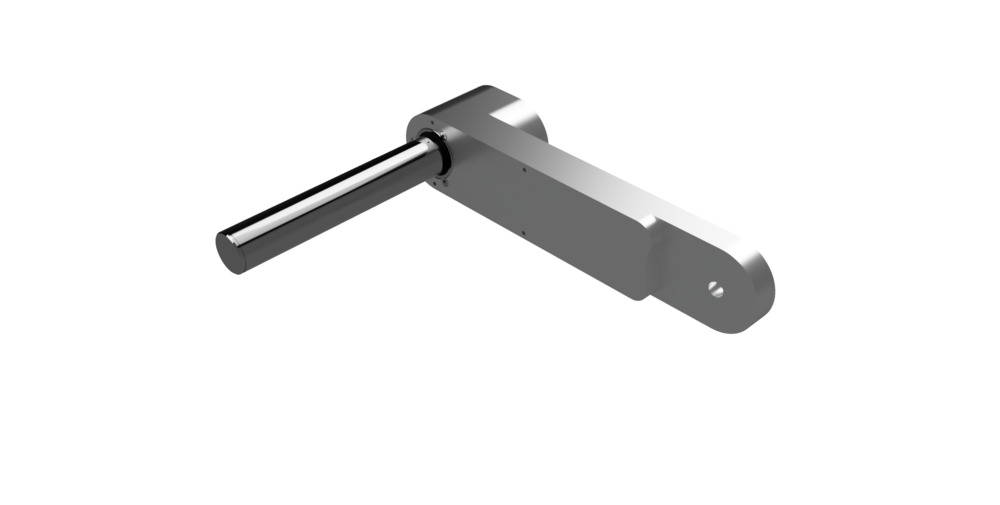

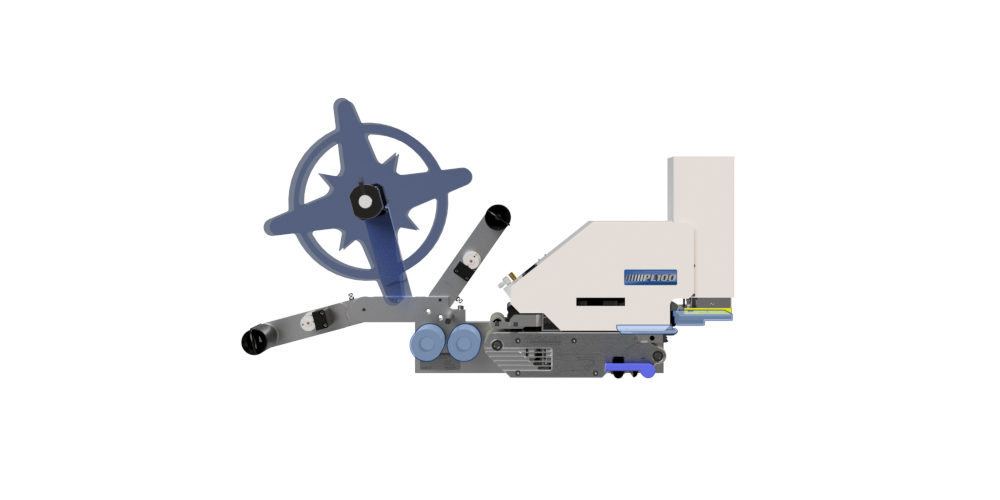

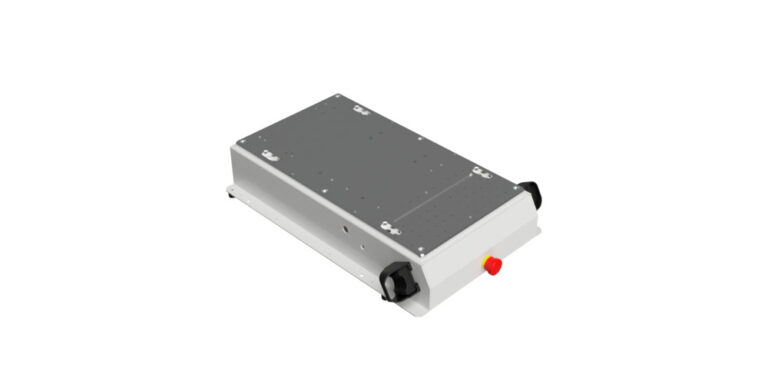

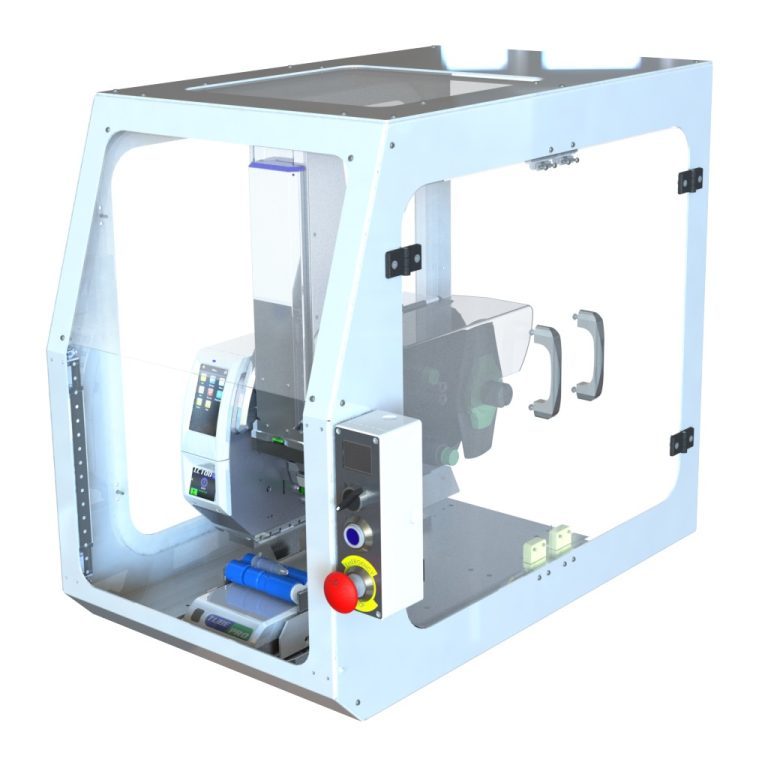

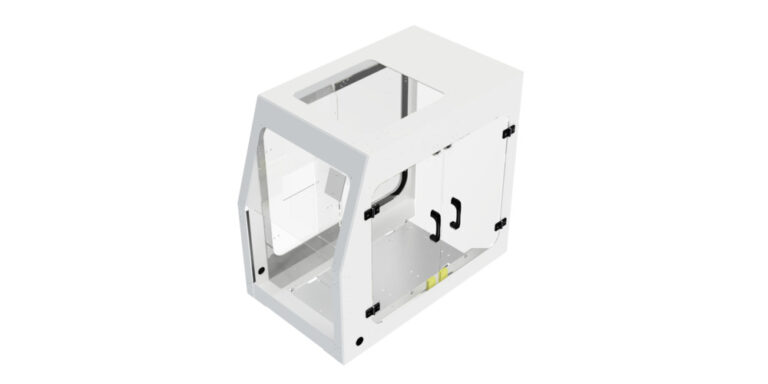

The “All-Electric” PL100r Feeder provides a highly accurate and reliable feed and peel system of virtually any shape of die-cut adhesive component. No pneumatics simplifies setup and maintenance. It provides capacity for components up to 100 x 100mm in size. The PL100r is configured specifically for integration with external Robotic or Picker devices. It includes all of the hardware necessary for operation including a Payoff assembly, and a powered Takeup (rewind) assembly. Custom Component Tooling (CCT) is the tooling package configured specifically for your die-cut component. The CCT items consist of a Blade Guide Pad and Liner Guide Roller. All CCT items are customized per the specifications of your material and are configured for rapid changeover which means no tools are required to remove or replace the tooling.

Features

- All-Electric Base Unit includes Payoff, and Powered Take-Up (Rewind)

- Configured for Integration into Automation

- Rapid Changeover Features

- Maximum Affordability

- 100 x 100mm Component Capacity

- Any Shape, Any Material, Multiple Simultaneous Placements

- Feed Accuracy: +/- 0.35mm (0.014″) or better (component dependent)

- Optional EP Package Accuracy: +/- 0.1mm (0.004″) or better (component dependent)

- 16-Key Applicator Interface Module (AIM) with LCD Display for Operator Input

More Popular Configurations

Design Your System

Accessories and Upgrades