Category: Products

-

LG100 Presenter

Description The LG100TM is our on-demand print and peel system, featuring our Label GlideTM presentation platen. This system is configured specifically for interface with customer robots. Customers can configure their robotic pick and place unit to remove the labels after the LG100 prints and presents the label. The LG100 provides maximum visibility of the printed…

-

Non‐Cylindrical Device Label Wrap Modules

Description Non-Cylindrical device shapes are also used in the Pharma and Healthcare market. These devices can include very stringent labeling requirements including application of labels and wrapping of labels around the circumference of the Device. Non-Cylindrical devices present very unique challenges for label wrapping specifically to ensure that the label is applied correctly and tightly…

-

PL Series TTP

PL100 and PL165 Series Applicators can be configured with a Thermal Transfer Printer (TTP) module to provide a ‘Print and Apply’ system. These systems are ideal for applications that don’t require ‘on demand’ printing and can be satisfied with batch printing. These Applicators provide all of the benefits of our PL Series Applicators with the…

-

PL100 Electric Tamp Mode

Electric Tamp Modules are available as a standard option on all Nautilus Systems, Inc. (NSI) PL100 and PL165 Applicator products. Key benefits of the Electric Tamp include rapid acceleration and deceleration, digital control of the tamp motion profile, elimination of all pneumatic cylinders and associated sensors and flow controls, and reduced compressed air consumption. Compressed…

-

PL100 Pneumatic Tamp Mode

PL100i Applicators with Pneumatic Tamps are the base configuration offered by Nautilus Systems, Inc. (NSI) for fully integrated placement systems. Pneumatic tamps provide excellent performance and are available in multiple actuator configurations, application forces, and stroke lengths. All PL100 units have capacity for 100 x 100mm Adhesive Components and in some cases can accommodate components…

-

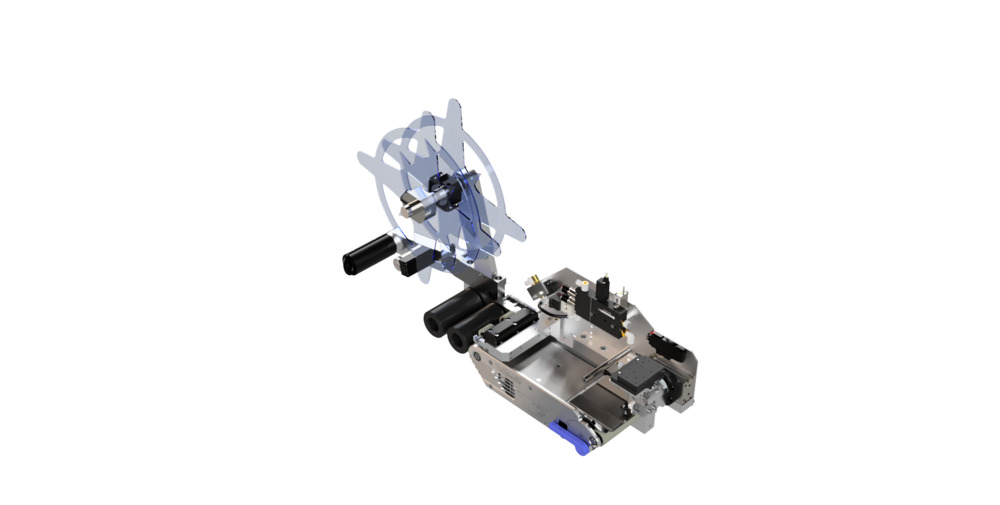

PL100 Robot Mode

Nautilus Systems, Inc. (NSI) All-Electric PL100 Robot Mode Feeders are configured specifically for integration with external Robotic or Picker devices to provide a highly accurate and reliable feed and peel system of virtually any shape of die-cut adhesive component. The Robot Mode Feeders include all hardware necessary for operation including the base Feeder, a Payoff…

-

PL100 Series

Description The PL165i provides highly accurate and reliable placement of virtually any shape of die-cut adhesive component. It provides capacity for components up to 100 x 165mm in size. The PL165i is configured specifically for integration into automated assembly solutions. It includes all of the hardware necessary for operation including a pneumatic precision-guided Tamp actuator…

-

PL100-RT180 Applicator

Description This Tamp configuration is available for either standard PL100 or PL100EP (extreme precision) Applicators. It is targeted for components up to 50 x 50mm in size. This module provides the unique function of removing the adhesive component from the liner on one plane and then rotating the adhesive component 180 degrees to reposition the…

-

PL100-RT90 Applicator

Description This Tamp configuration is available for either standard PL100 or PL100EP (extreme precision) Applicators. It is intended for components up to 50 x 50mm in size. This Tamp configuration provides the unique function of removing the adhesive component from the liner on one plane and then rotating the adhesive component 90 degrees to reposition…