-

Integrated Inspection

Based on customer demand and emerging industry trends NSI has focused specifically on providing systems that allow an adhesive component, label or other die-cut adhesive part, to be inspected prior to placement on a substrate…

-

Print and Apply Automation

NSI, using our print and apply applicator products has configured dedicated automation systems for specific print and apply applications. For Tube and Vial Labeling we offer our FLEX Tube Pro systems. For complex label and…

-

LG100 Presenter

Description The LG100TM is our on-demand print and peel system, featuring our Label GlideTM presentation platen. This system is configured specifically for interface with customer robots. Customers can configure their robotic pick and place unit…

-

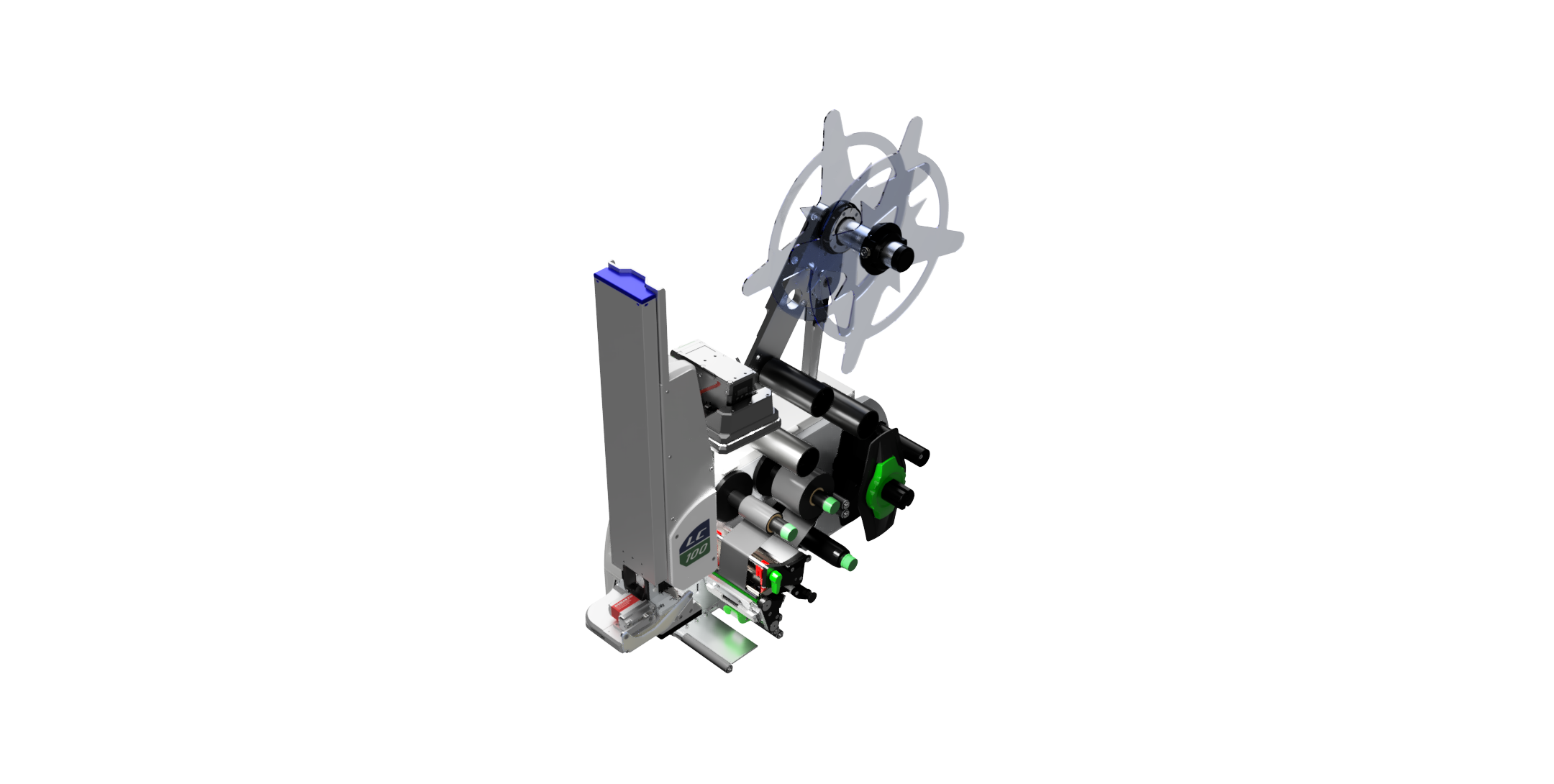

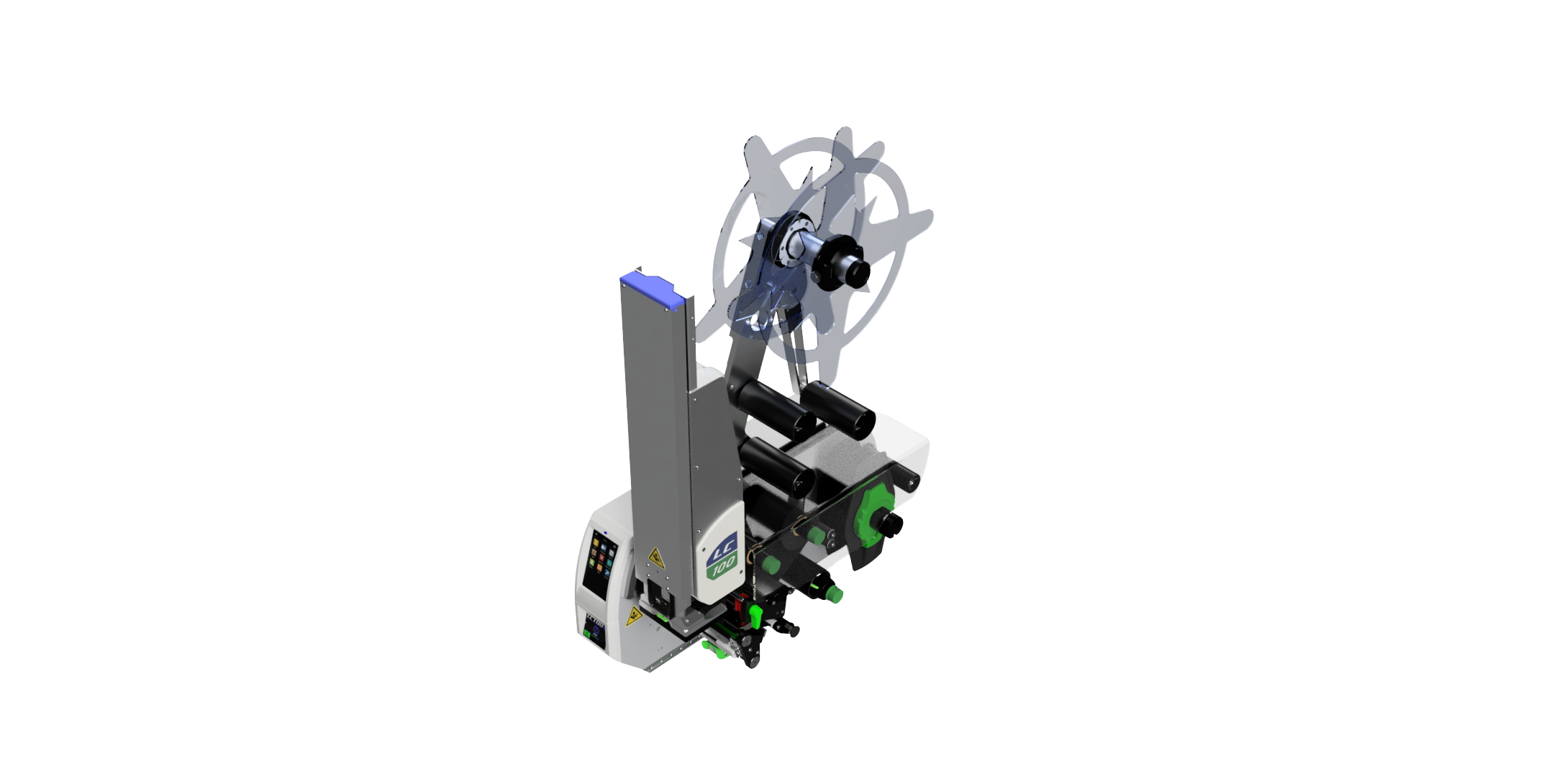

LC100i-C Applicator

Description The LC100i-CTM is a compact configuration of our highly advanced on-demand ‘print and…

-

LC/LG – On Demand

LC100TM Series Print and Apply and LG100TM Label Glide Systems are NSI’s offering for…

-

PL Series TTP

PL100 and PL165 Series Applicators can be configured with a Thermal Transfer Printer (TTP)…

-

LC100i-PVA

Description The LC100i-PVATM is a game changing implementation of print and apply technology. PVATM…

-

PL100r-TTP and PL165r-TTP

Description The PL100r-TTPTM and PL165r-TTPTM provide an excellent package for precision print and apply…