Tamp modules serve several important purposes in our Applicator products including: as a system for quick-change mounting of vacuum chucks; vacuum delivery system; and precision motion used to transfer an adhesive component from the peel position to the apply position. Our standard Tamp Module provides 175mm of vertical guided precision stroke. However, some applications require a special Tamp configuration. In our efforts to serve our customers over the years we have developed several specialized Tamp Modules to meet a variety of needs. From increased stroke to special rotations of the adhesive component we offer specialized modules that can be mounted to our r-series Feed and Peel systems to provide an integrated solution.

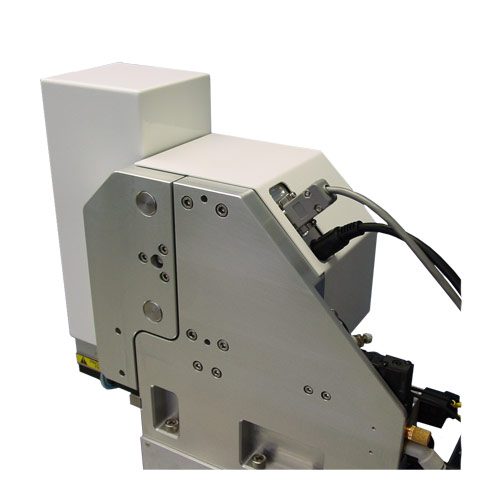

Standard Tamp Module

The standard Tamp is included with all i-series Applicators (PL100i, PL165i, PL100EPi, PL165EPi, etc). This module provides 175mm of precision guided vertical motion utilizing a pneumatic actuator.

To learn more about the Standard Tamp Module CLICK HERE.

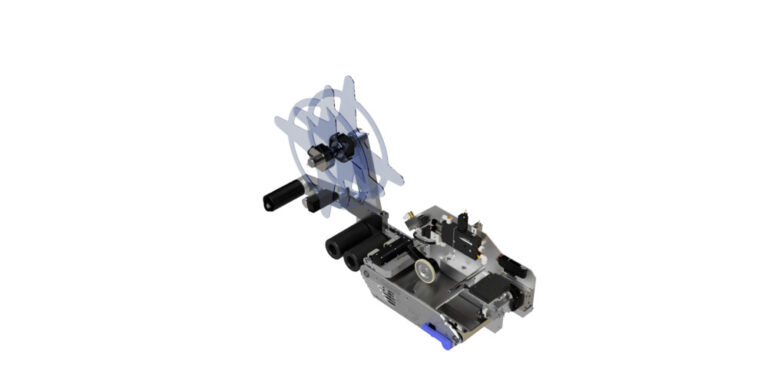

RT90 Tamp Module

This module is available for integration on PL100r and PL100EPr Feed Systems. It is intended for components up to 50 x 50mm in size. This module provides the unique function of removing the adhesive component from the liner on one plane and then rotating the adhesive component 90 degrees to reposition the adhesive component on a plane perpendicular to the peel surface with the exposed adhesive surface facing away from the vacuum chuck.

To learn more about the RT90 Tamp Module CLICK HERE.

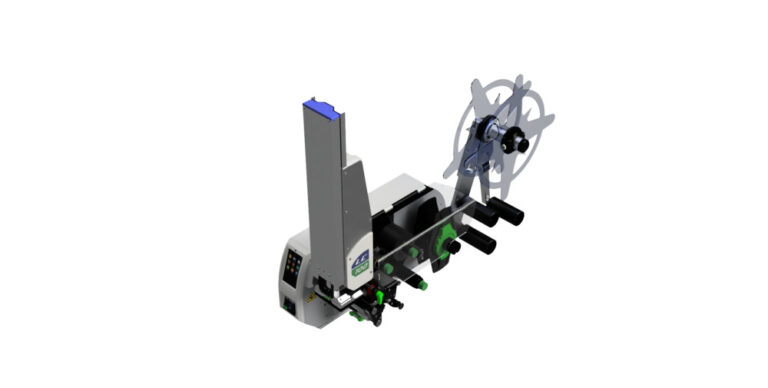

Sidescan Tamp Module

This module provides an additional axis of motion control to allow the Tamp to move on a horizontal plane. This module is typically used in applications in which the die-cut adhesive components may include variation in their position on the liner, in the non-feed or cross-web axis, that exceeds the allowable specifications for assembly.

To learn more about the Sidescan Tamp Module CLICK HERE.

Dual Force Tamp Module

This is an optional upgrade to the Standard and Extended Tamp Modules in which the applciation force can be doubled from standard. This option includes a second pneumatic actuator affixed to the Tamp to provide the additional force.

To learn more about the Dual Force Tamp Module CLICK HERE.

Extended Stroke Tamp Module

This module is identical in design and function to the Standard Tamp with the exception that it increases stroke to 400mm. The module includes the same class of precision bearings and pneumatic actuator but with the increased stroke.

To learn more about the Extended Stroke Tamp Module CLICK HERE.

RT180 Tamp Module

This module is available for integration on PL100r and PL100EPr Feed Systems. It is intended for components up to 50 x 50mm in size. This module provides the unique function of removing the adhesive component from the liner on one plane and then rotating the adhesive component 180 degrees to reposition the adhesive component in an ‘upside down’ orientation relative to the peel surface with the exposed adhesive surface facing away from the vacuum chuck.

To learn more about the RT180 Tamp Module CLICK HERE.

Electric Tamp Module

Our ET200 Electric Tamp Module is available as a standard option on all of our PL100 and PL165 Applicator products. Key benefits of the ET200 include rapid acceleration and deceleration, digital control of the tamp motion profile, elimination of two pneumatic cylinders and associated sensors and flow controls, and reduced compressed air consumption.

To learn more about the Electric Tamp Module CLICK HERE.